Products - R10 Premium Series

Product Size: 2m x 20m x 2.0mm │ 40m²/roll │ 120kg/rollThe R10 Premium Series also known for Safety Floor represents the pinnacle of vinyl flooring innovation, combining superior durability with exceptional aesthetic appeal. This premium collection features advanced surface treatments and cutting-edge design technology to deliver outstanding performance in high-traffic commercial and residential applications.

Installation

Subfloor must be smooth, hard, clean and dry prior to installation. Where applicable, the subfloor must incorporate an effective damp proof membrane. The material must be allowed to acclimatize for 24 hours before installation in a room temperature between 18 - 24°C. Matching welding rods are required for heat welding applications.

Maintenance

Regular maintenance is essential to retain the appearance and durability of the floor. The floor covering should be maintained with regular sweeping and mopping using a neutral cleanser. For more intensive cleaning, use a fine spray cleaning pad under a floor machine, or for larger areas, combined machine cleaning with appropriate cleaning solutions.

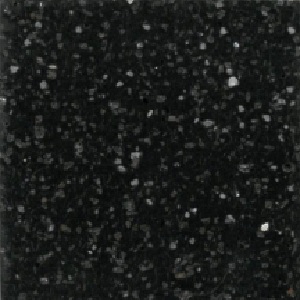

R10-001

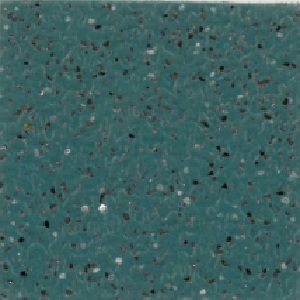

R10-002

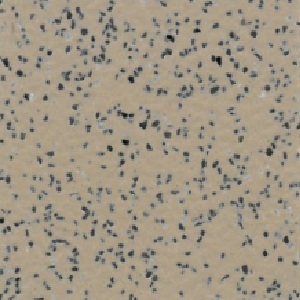

R10-003

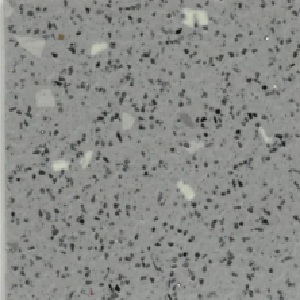

R10-004

R10-005

R10-006

R10-007

R10-008

R10-009

R10-010

R10-011

R10-012

Description

| Total Thickness | EN 428 | mm | 2.0 |

| Weight | EN 430 | g/m2 | 2.0 mm = 120kg/roll |

| Width | EN 426 | m | 2 |

| Length of Sheet | EN 426 | m | 20 |

Classification

| European | EN 685 / EN 649 | ||

| Classification K | K5 | ||

| NF P 92 506 | M1 | ||

| EN 13 501 - 1 | Class Bfl - S1 | ||

| Fire Rating | DIN 4102 | B1 | |

| ASTM E662 | < 400 | ||

| ASTM E648 | class 1 | ||

| Electrical Resistance | EN 1815 | KV | < 2 |

| EN 1081 | Ohm |

>109-10 | |

| Slip Resistance Dry | EN 13893 | ³ 0.3 | |

| Slip Resistance Wet | DIN 51130 | R10 |

Performances

| Abrasion Group | EN 649 | P | |

| Abrasion Resistance | EN 660.1 | mm | 0.15 |

| Castor Wheel Test | EN 425 | excellent | |

| Colour Fastness | EN 20105 - B02 | >= | 7 |

| Chemical products resistance | EN 423 | excellent | |

| Dimensional Stability | EN 434 | % | ≤ 0.25 |

| Flexibility | EN 435 | excellent | |

| Hygiene Treatment | MRSA | excellent | |

| Indentation | EN 433 | mm | approx. 0.06 |

| Residual Indentation | EN 433 | mm | approx. 0.05 |