Products - Antistatic ESD Homogeneous Flooring

Product Size: 600 x 600 x 2.0mm │ 28 tiles/ box │ 10.08 m²/ box │ 108.50 ft²/ boxDurafloor ESD Antistatic flooring is crucial for protecting sensitive electronics and equipment from damage caused by static electricity. This advanced ESD (Electrostatic Discharge) flooring solution works by effectively grounding and dispersing static charges, preventing the buildup of voltage that can harm sensitive devices. Durafloor ESD Antistatic tiles are specifically designed to conduct and dissipate static electricity, providing a reliable pathway to ground for optimal protection in critical environments.

With its advanced ESD properties, Durafloor ESD Antistatic flooring offers several key benefits. Firstly, it provides a safe and reliable environment for sensitive electronics, reducing the risk of damage caused by static electricity. This is particularly important in industries such as semiconductor manufacturing, laboratories, and research facilities, where even small amounts of static can cause significant harm.

Installation

Subfloor to be smooth, hard, clean and dry prior to laying. Where applicable the subfloor most incorporate and effective Damp proof membrane. The material must allowed to be acclimatize 24 hours before installation in a room temperature of between 18 - 24°C. Match welding rods are required for heat welding on ground floor

Maintenance

An emulsion dressing is required. Maintenence should be carried out regurlarly to retain the appearance and durability of the floor. The floor covering should be maintained with regular sweeping and mopping using a nuetral cleanser, more intense cleaning should be carried out using a fine spray cleaning pad under a floor machine, or for larger areas combined machine cleaning.

AS-0002 Techno Ice

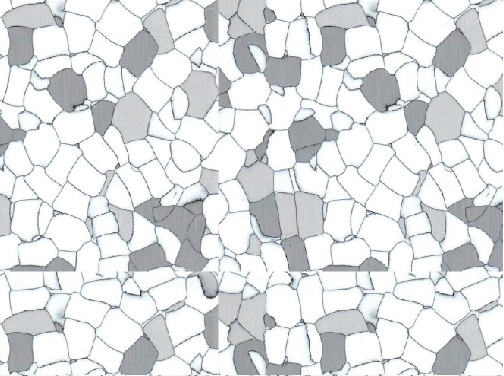

AS-0112 Electro Pebble

ESD Accesories

Description

| Total Thickness | EN 428 | mm | 2 |

| Weight | EN 430 | g/m2 | 3400 |

| Width / Length of Sheet | EN 426 | mm | 600 x 600 |

Classiffication

| Standard / Product Specification | EN 649 | - | Homogeneous vinyl flooring |

| European Classification | EN 685 | class | 34 - 43 |

| K rating | - | - | K5 |

| Fire Rating | EN 13 501 - 1 | - | Class Bfl - S1 |

| ASTM 648 | - | Class 1 | |

| Electrical Resistance | EN 1081 | Ohm | 106≤ R ≤ 108 |

| CEI 61340-4-1 | Ohm | 106≤ R ≤ 109 | |

| ASTM / ESD 7.1 | Ohm | 106≤ R ≤ 108 | |

| Static Electrical Propensity | EN 1815 | V |

< 200 |

| CEI 61340-4-5 | V | <200 | |

| Slip Resistance Dry | pr EN 13893 | - | DS |

| Slip Resistance Wet | DIN 51 130 | - | R9 |

Performances

| Wear Resistance | EN 660.1 | mm | ≤ 0.30 |

| Wear Group | EN 649 | M | |

| Dimensional Stability | EN 434 | % | sheet≤ 0.40 tile≤ 0.25 |

| Residual Indentation | EN 433 | mm | ≤ 0.10 |

| Thermal Conductivity | EN 12 524 | W / (m.K) | 0,25 |

| Colour Fastness | EN 20 105 - B02 | - | ≥ 6 |

| Chemical Resistance | EN 423 | - | Good |

| Anti Bacterial and Fungicidal | EN ISO 846 | - | Yes |